Starpro Sanwa Ayutthaya Modified Starch Co., Ltd. (SSAMS) was established in 2016 by P.M.I. Business Group and Sanwa Starch Co., Ltd. in Ayutthaya, Thailand. It is the most innovative food grade pre-gelatinized starch company with the biggest capacity in Asia-Pacific.

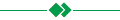

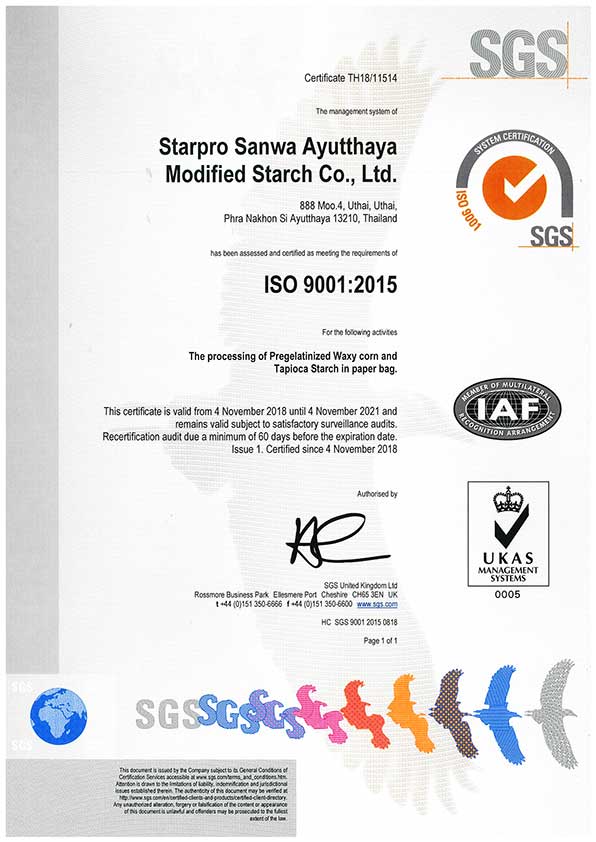

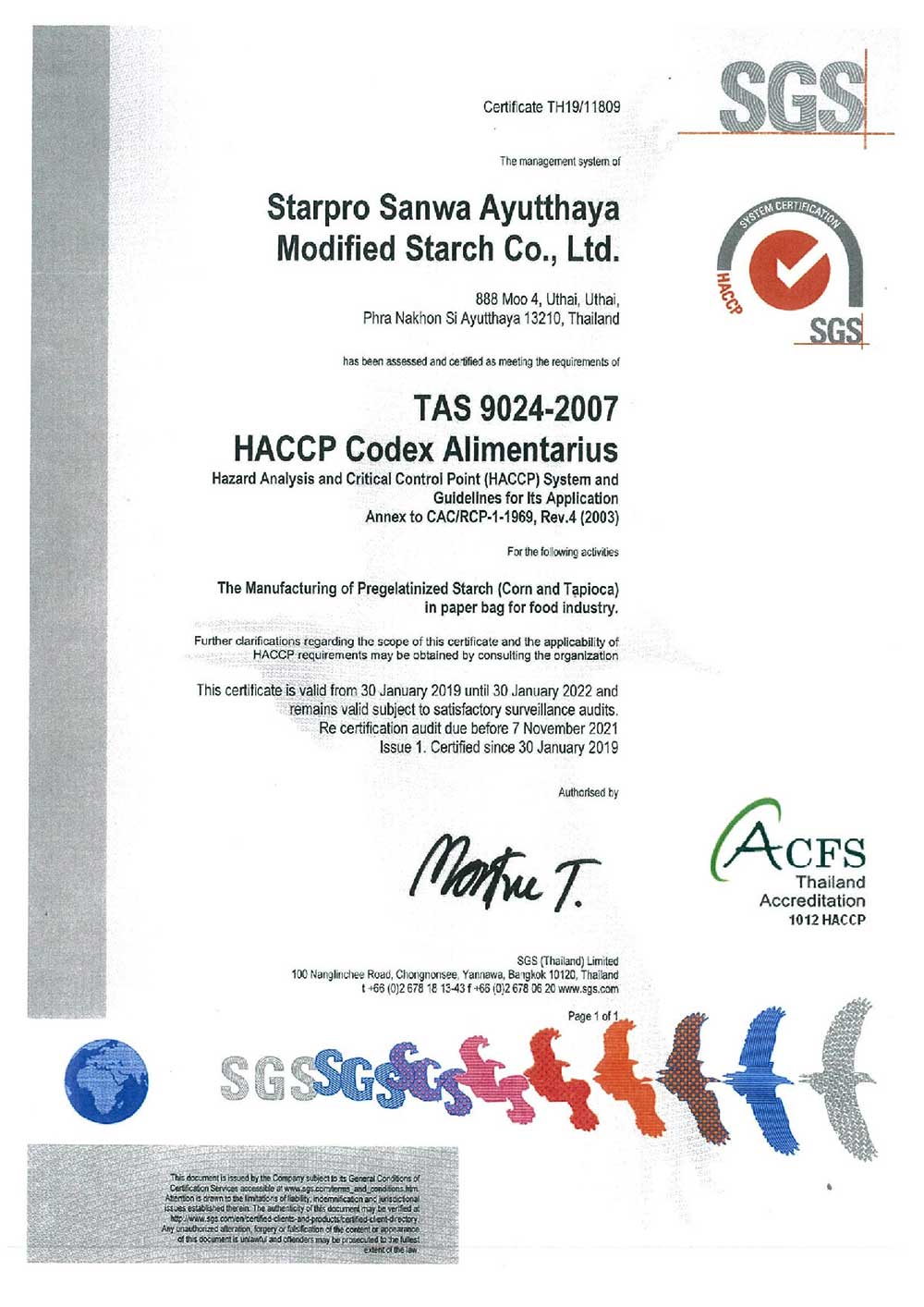

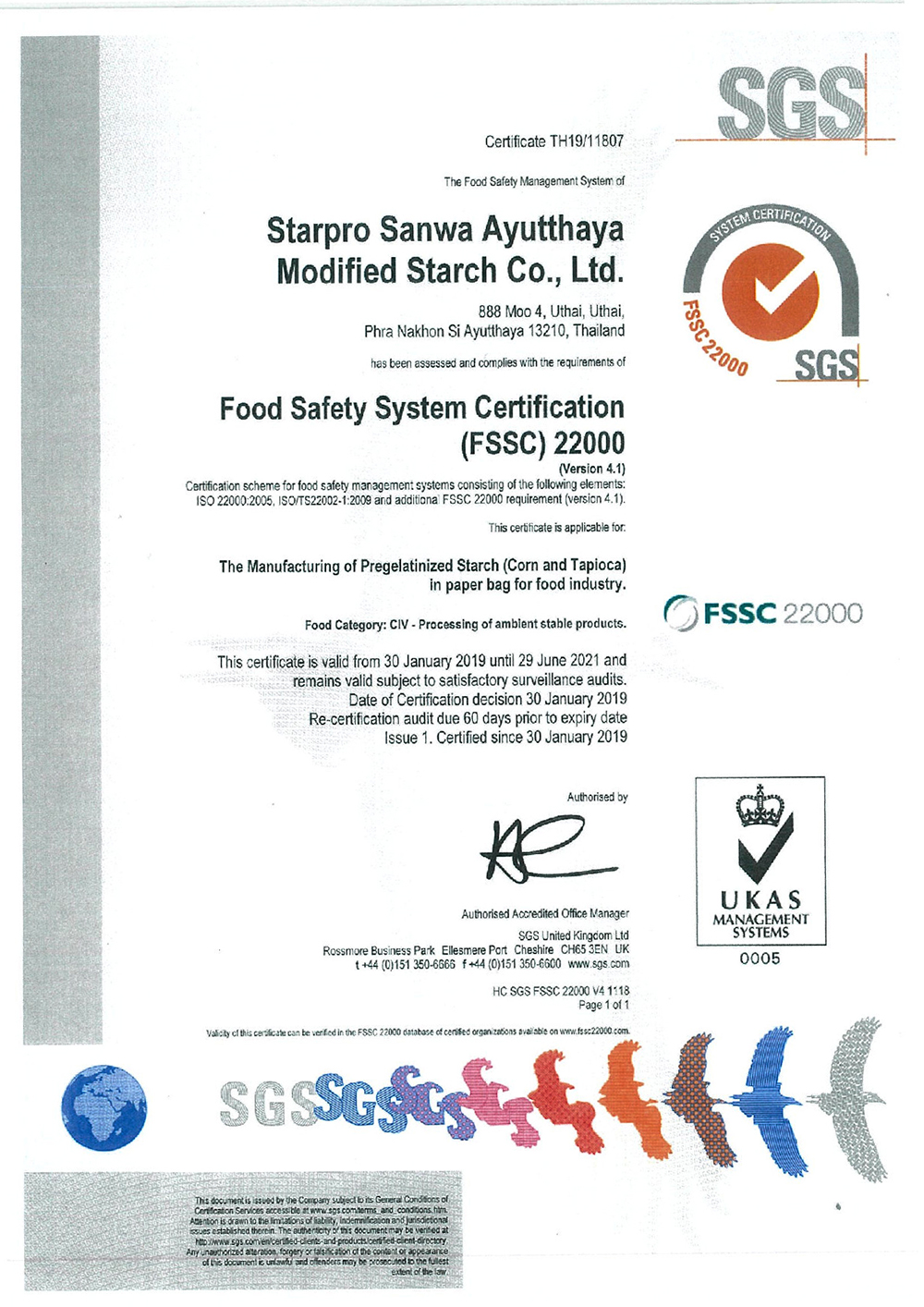

SSAMS is built on the premise of food safety, therefore, we adopted an advanced enclosed plant design. With respect to the flow of pipelines, factory planning and the materials for equipment, everything adheres to strict food safety regulations. To minimize food safety risks, we have implemented a highly automated production system, reducing personnel intervention. Further, we introduced a comprehensive quality control system. All products are packaged inside an ISO8-class clean room to ensure safe and flawless products.

In terms of technology, SSAMS has implemented pre-gelatinization and humidity-control technology from Sanwa Starch, enhancing our product stability and application range.

SSAMS upholds food safety as the highest business principles and dedicates to the creation and improvement of application of pre-gelatinized starches. While constantly refining the process management to ensure the product's competitive advantages, SSAMS also keeps close communication with the market and industry experts to provide the safest and best pre-gelatinized starch products.